An anonymous maker decided that the 4GB of RAM in their Raspberry Pi 400 was too limiting — so, armed with a hot-air rework station, upgraded it to a more capacious 8GB.

An anonymous maker decided that the 4GB of RAM in their Raspberry Pi 400 was too limiting — so, armed with a hot-air rework station, upgraded it to a more capacious 8GB.

Designed for use with a customizable launch vehicle, these 3D-printed rocket engines can be turned around in a few days.

Chennai-based Agnikul is looking to make it possible to offer rapid-turnaround on-demand space launches — by 3D printing custom rocket engines and other components in less than three days.

“We are building a launch vehicle that carries a payload capacity of 30 to 300 kilograms [around 66-660lbs], depending on the needs of the customers,” Agnikul’s chief operating officer Moin SPM tells IEEE Spectrum in an interview. “We are trying to provide a rapid, on-demand launch service by 3D-printing the entire rocket engine in one shot.”

Sometimes advances happen when someone realizes that a common sense approach isn’t the optimal one. Take radio. Success in radio requires bigger antennas and more power, right? But cell phones exist because someone realized you could cram more people on a frequency if you use less power and smaller antennas to limit the range of each base station. With FDM 3D printing, smaller nozzles were all the rage for a while because they offer the possibility of finer detail. However, these days if you want fine detail you should be using resin-based printers and larger nozzles offer faster print times and stronger parts. The Volcano hotend started this trend but there are other options now. [Stefan] over at CNC Kitchen decided to make his own high flow nozzle and he claims it is better than other options.

Don’t get too carried away with the DIY part. As you can see in the video below, he starts with a standard nozzle, so it is really a nozzle conversion or hack. The problem with high flow isn’t the hole in the nozzle. It is melting the plastic fast enough. The faster the plastic moves through the nozzle, the less time there is for it to melt.

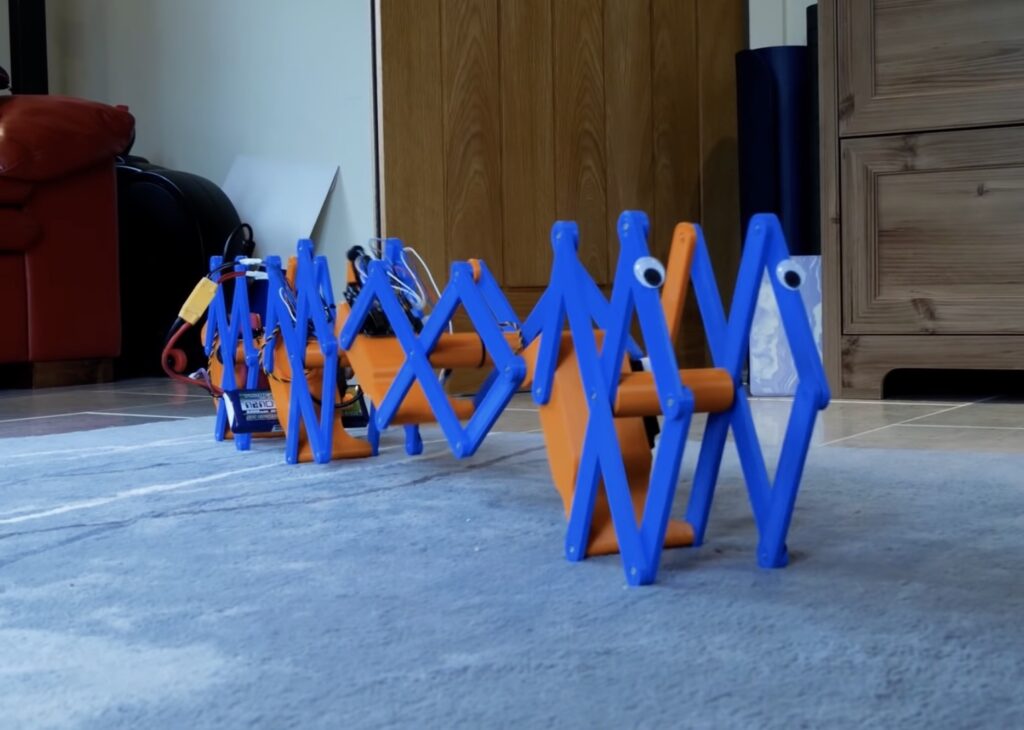

Self-propelling robots come in a whole host of shapes, sizes, and capabilities, with some being able to fly while other can walk on just a couple or many legs. But YouTuber James Bruton wanted to innovate on this concept even further by designing and building a robot that mimics an earthworm through extending and contracting segments at certain times to slowly inch along the ground. This class of motion is called peristalsis, and it works by constricting a ring of muscles to propagate material, such as in the case of the digestive tract, or to move an entire body.

3D printers are very popular in the maker community and CNC machines complement them well. While 3D printers fabricate parts by adding material over time, CNC mills and routers fabricate parts by subtracting material. That is preferable when working with large parts or when you require a lot of precision. If you want an affordable option, this guide will show how to build Ivan Miranda’s 3D-printed CNC machine design.

In addition to being a filesystem, ZFS is a storage array and volume manager, meaning that you can feed it a whole pile of disk devices, not just one. The heart of a ZFS storage system is the zpool—this is the most fundamental level of ZFS storage. The zpool in turn contains vdevs, and vdevs contain actual disks within them. Writes are split into units called records or blocks, which are then distributed semi-evenly among the vdevs.

Sometimes it’s good to be a little bad.

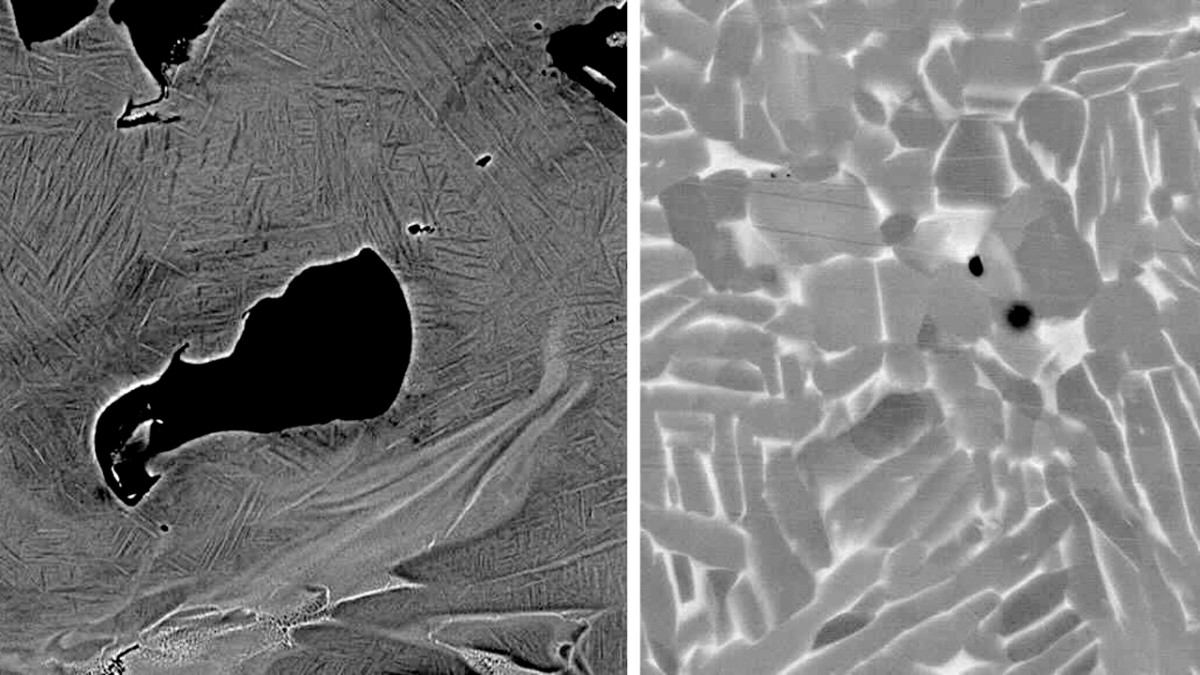

Cornell researchers found a counterintuitive way of improving 3D-printed metal alloys. By deliberately introducing more defects into the printing process, followed by a post-processing treatment that uses high temperature and high pressure to change the material’s microstructure, they turned the defects into assets, resulting in a stronger, more ductile metal product.

Pseudonymous maker “hoarsecheerleader” has turned a Raspberry Pi 4 into an in-car retro gaming system — for backseat passengers only of course — using an all-in-one display case and a 12V power supply.

The Raspberry Pi has long been popular for retro-gaming projects, thanks to a combination of low cost yet impressive performance in a small package. It’s also the heart of more than a few in-car entertainment upgrades — but hoarsecheerleader’s project combines the two.

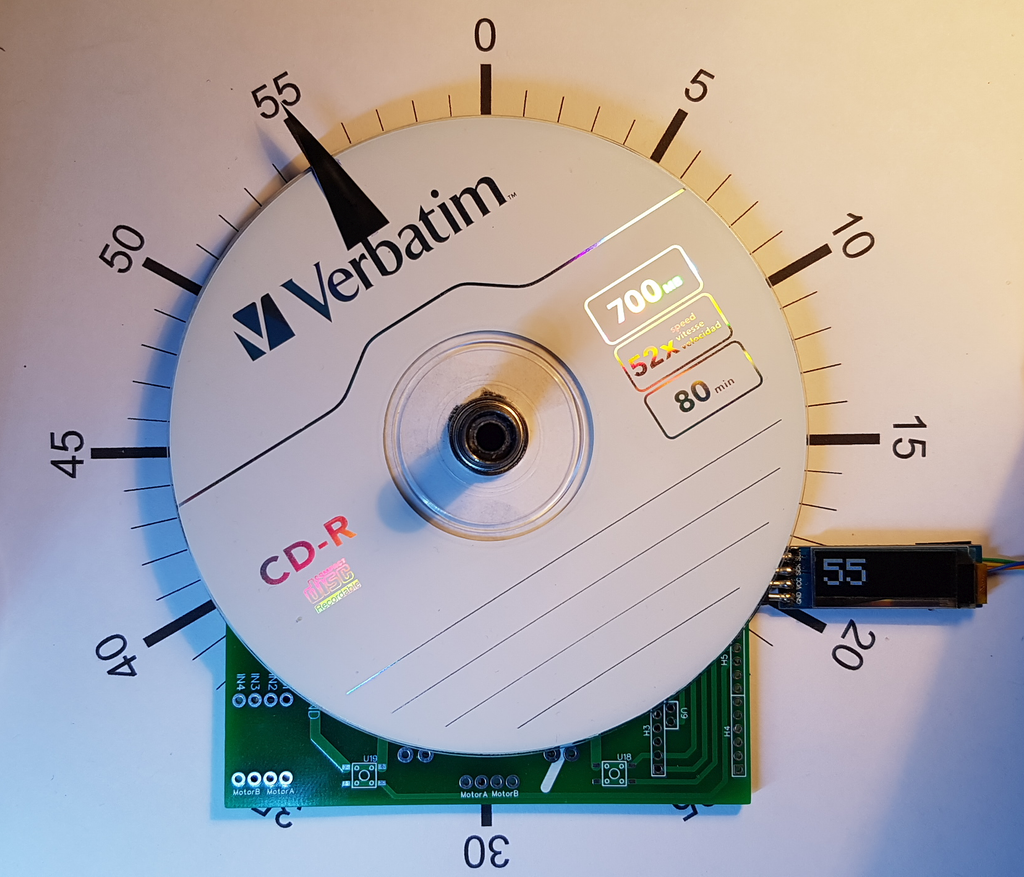

I made a rotary encoder. Due to its 60 steps (6 degree) resolution it suits to make clocks.

There is a very good and detailed description of the single track Gray code here: https://www.ncbi.nlm.nih.gov/pmc/articles/PMC6111776/.

My instructable is only about physical realization now.

Earlier this year multiple startup companies announced they were aiming to bring edible chicken created from stem cells to market by 2022. For an eyebrow-raising price. Now, researchers in Japan say they’ve 3D printed a version of Wagyu beef: i.e. meat from the eponymous Japanese cattle, which is famous for its marbling and how much it costs. Which we can only assume will be far less if/when it starts coming from 3D bioprinters.