Sometimes it’s good to be a little bad.

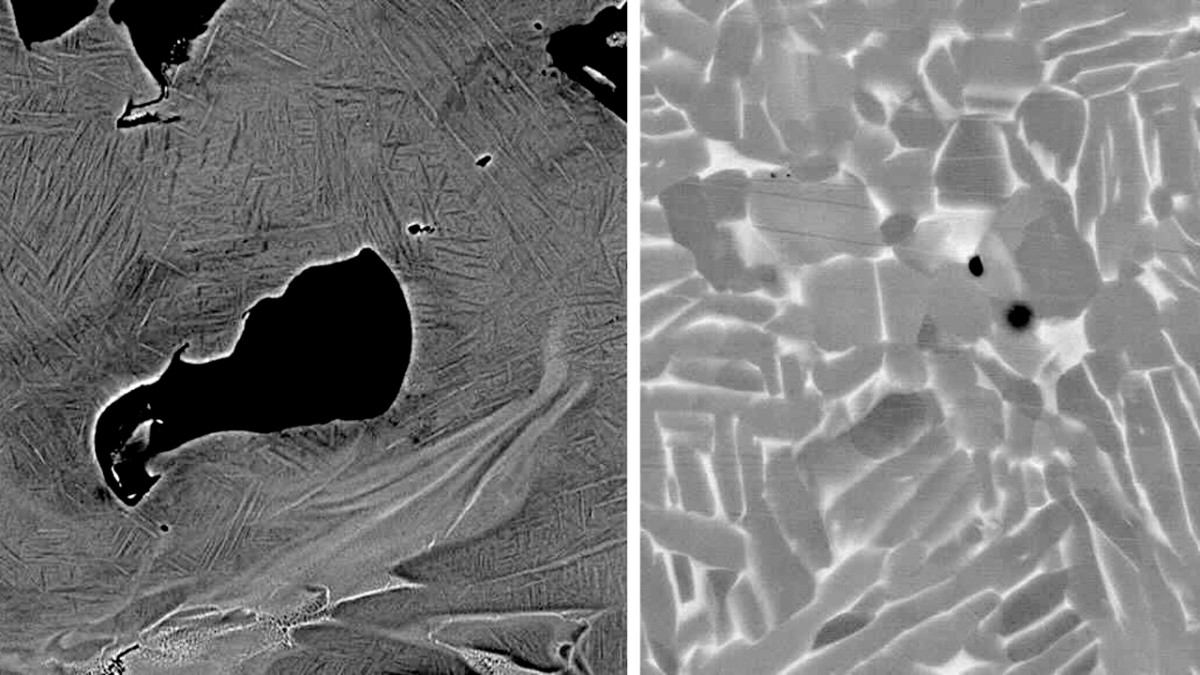

Cornell researchers found a counterintuitive way of improving 3D-printed metal alloys. By deliberately introducing more defects into the printing process, followed by a post-processing treatment that uses high temperature and high pressure to change the material’s microstructure, they turned the defects into assets, resulting in a stronger, more ductile metal product.