Finally, we can purchase affordable 32-bit controllers for our 3D Printers! In this video I show configuring the board with Marlin 2.0 for my HyperCube 3D Printer.

3D Printing

Look inside the 3D-printed Mars home that NASA awarded $500,000

When you think of future Martian habitats, what do they look like? A squat, half buried, windowless dome? A glorified fallout shelter? Or … how about … this? This is Marsha. Designed by AI SpaceFactory. It has windows, multiple floors, private rooms, and even a skylight. But best of all? NASA loves it.

The rocket scientists and engineers at NASA are pros when it comes to landing robots on Mars. And they’re figuring out how to get humans there next. But when it comes to living on Mars? Well, they decided to ask the public for help. In the 2010s, NASA launched its 3-D Printed Habitat Challenge. Over the years, its held multiple stages of the phases of the challenge that started with virtual designs and has since progressed to full-fledged 3-D printed models.

3D Printing Troubleshooting Guide: Pillowing

While getting a great bottom layer is great, a fantastic top layer isn’t possible if you’re suffering from pillowing; the dreaded lack of filament on the top layers that leave your prints looking like swiss cheese. Learn how to avoid pillowing with Alec – check it out!

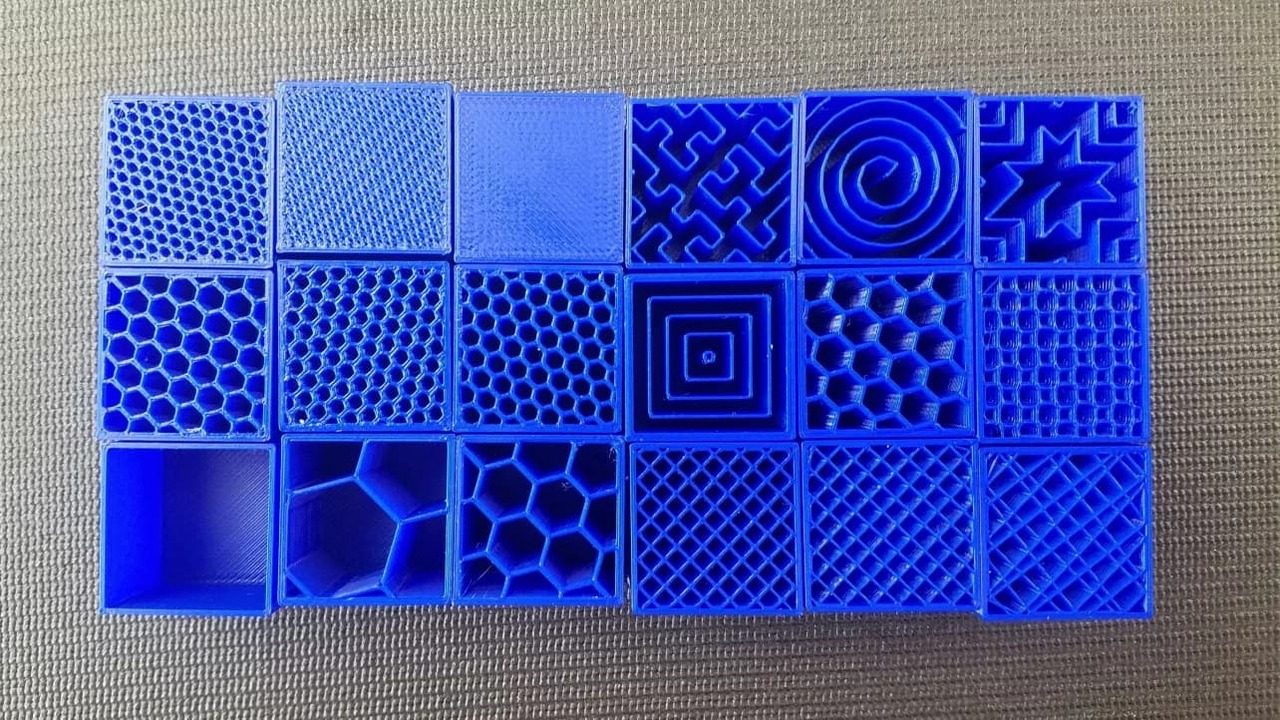

What’s the Best Cura Infill Pattern for You Needs?

Quite often, 3D printing is used to produce parts that could just as easily be made using another manufacturing technique. Yet, although the final results might look the same on the outside, what’s inside could be drastically different.

A major benefit (and necessity) of 3D printing is that parts can be varying degrees of hollow. From a production perspective, this reduces material and cost as well as the weight of the final product. And from a printing perspective, it saves valuable time!

Ender 3 upgrades: EZR to direct drive adaptor and all in one rear mounted electronics case

I’ve put some hours into CAD this week, designing two upgrades to improve my Ender 3 that you can benefit from too.

The first is an adaptor to join my two favourite Ender 3 extruder mods together: the direct drive kit from Basaraba Innovations and the EZR extruder. This simple part gives reliable and convenient filament loading, with improved printing performance.

The second aims to tidy up my electronics, which were accessed underneath the printer and had buck converters and other components loose. I’ve created a modular system for mounting the electronics at the back of the machine, to suit the standard Creality board, an MKS Gen L or an SKR 1.3. There are also mounts for TL smoothers, a raspberry pi, a buck converter and two relays. The cooling fan is now much quieter and can be upgraded to a 40x20mm design without issue.

Making 3D Printer filament from failed prints.

Using the 3Devo Composer to turn failed prints into new filament for your 3D printer!

Four ways to beat moire on your 3D printer

Moire can ruin an otherwise beautiful 3D print.This artefact is caused by irregular extruder steps or pulses, leaving a repeating pattern on the surface. It can be really tricky to tune out, with different printers experiencing it for different reasons.

My Cocoon Create Touch / Wanhao Duplicator i3 Plus / Monoprice Makerselect has it worse than most printers out there, exacerbated by the accuracy of the flexion extruder. In this guide, I’ll show you four potential solutions for beating moire. With any luck one or more of them will fix your problem. Fortunately, only one needs to work!

There are a lot of theories on why moire exists, and this is beyond the scope of this video. For this reason I’ve kept it simple, so keep this in mind before commenting. The example of the rounding teps is grossly simplified too which I am aware of. This video is about solutions, not problems.

TOP 3D Printers for the 2019 Maker’s Muse Studio (FDM/FFF)

With countless 3D Printer reviews, it takes a lot to earn a place in the Maker’s Muse studio. Ever wondered what machines he use everyday? Watch to find out!

Creawesome Mod tested on Ender 3, Ender 5 and CR-10S Pro

Creawesome Mod is a Cura alteration that aims to improve print quality through changes to the machine settings and slicer profiles. It is well documented and free. The only question is: does it work? Regardless of your results, be appreciative of the fact that someone has worked tirelessly to improve your experience, and not charged a cent for it.