Step by step instructions for making the 600W, 3d-printed Halbach array brushless motor.

Overview and building instructions: https://www.instructables.com/id/600-…

3D Printing

Alternative-meat startup is hoping a 3D-printed steak can upend the meat industry

It may look like Play-Doh. But it’s actually a 3D-printed steak.

It’s made by the Israeli alternative-meat startup Redefine Meat, and the technology behind it is one of many contenders in today’s sizzling-hot international race to capitalize on the growing faux-meat market.

Redefine Meat isn’t focusing on alternatives to ground beef or sausages, but whole-cut steaks — an area of the market that has yet to hit the mainstream.

Arduino CNC Foam Cutting Machine (Complete Guide)

In this video we will learn how to build an Arduino CNC foam cutting machine. This is a typical DIY CNC machine because it’s made out of simple and cheap materials, some 3D printed parts and it has an Arduino as a controller.

3D Printing Greener Buildings Using Sustainable Building Material Made From Local Soil

The construction industry is currently facing two major challenges: the demand for sustainable infrastructure and the need to repair deteriorating buildings, bridges, and roads. While concrete is the material of choice for many construction projects, it has a large carbon footprint, resulting in high waste and energy expenditure. Today, researchers report progress toward a sustainable building material made from local soil, using a 3D printer to create a load-bearing structure.

The researchers will present their results today at the American Chemical Society (ACS) Fall 2020 Virtual Meeting & Expo. ACS is holding the meeting through Thursday. It features more than 6,000 presentations on a wide range of science topics.

3D Printed – Ender 3 LCD Cover with drawers

Found a nice useful full cover for the Ender 3 LCD with included drawers. Extra space always comes in handy to store tools or spare parts.

Download it now from Thingiverse

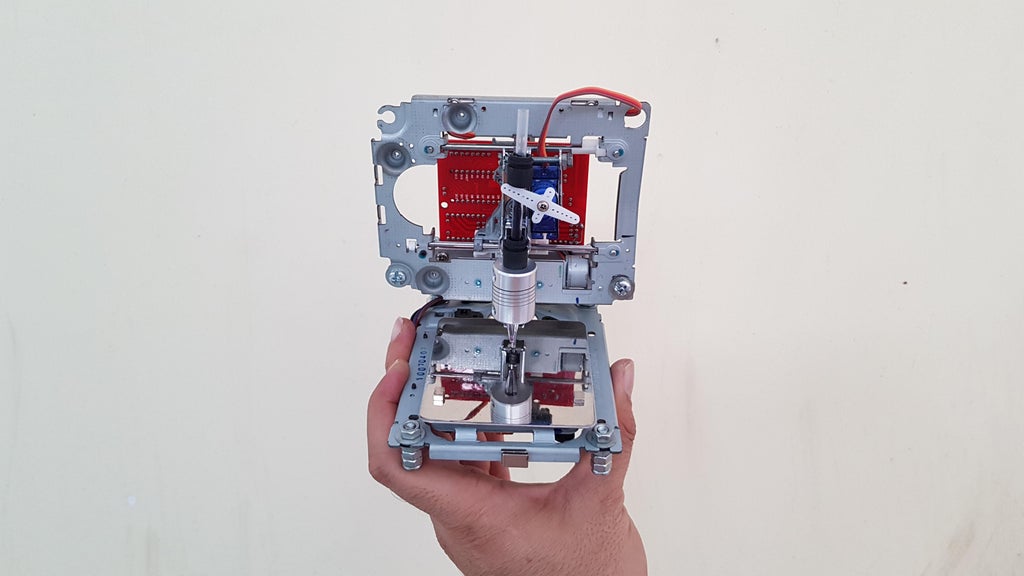

Back to Basic – Mini CNC Plotter

There are many projects and tutorials related to recycle old CD/DVD players into a mini CNC Plotter based on Arduino.

I have become too concerned with complicated details or new things, and now I should concentrate on basic, simple and important ideas. Getting back to basics, to start learning CNC, today I’d like to share how to easily build your own low-cost Arduino Mini CNC Plotter. With my version, I used the spring part of stapler as a main component for pen lift. During the process of doing this, I have referenced from many sources, studied & tried to clarify some point hard to grasp.

S42B closed loop stepper motors – No more layer shifts!

If you’ve ever had a failed print from a layer shift, you know how frustrating it can be. Traditionally 3D printers use open loop stepper motors, which means if they lose steps, the printer doesn’t know and can’t compensate. The Bigtreetech S42B is a closed loop stepper motor, which means it monitors the position of the stepper and will compensate for errors. This means no more layer shift failures.

3D QR Code Generator, So You Can 3D Print Custom QR Codes

Want to have your WiFi as a QR Code sign in your home for quests? Looking to display a massage or provide information via a clean “modern” application?

Check out the 3D QR Code generator that can export to STL!

Is it possible to destroy a 3D printer by moving the axes by hand?

In this video I show if it’s possible to destroy a 3D printer by moving the axes by hand. For this experiment I use my old Anet A8 because that’s the best thing I can do with this printer xD. The reason for this experiment is that I got several comments from people saying that it’s not smart to move your axes by hand because it might destroy your main board. I hope that this video gives a bit of insight about this phenomenon.

3D printer calibration revolutionised – Step by step to better print quality

This started with a request by my Patron magruder13: make an all in one calibration video to avoid needing to go through multiple old videos. Rather than just rehash into one video, I’ve gone a lot further: