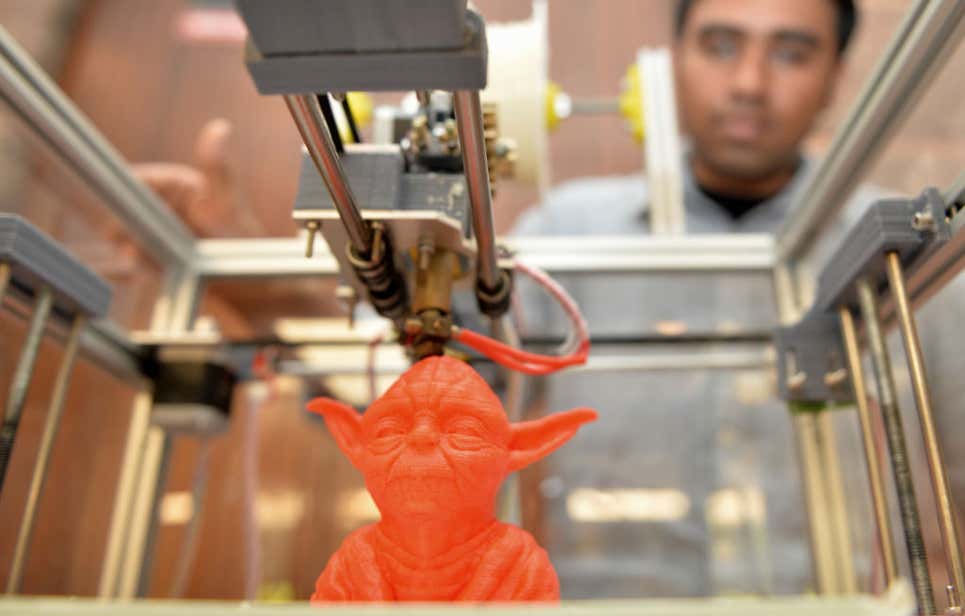

Two researchers at Penn State have created a new system for five-axis additive 3D-printing that reduces the amount and density of support materials needed for making printed objects.

In a paper entitled “Process planning for five-axis support free additive manufacturing,” doctoral candidates Xinyi Xiaoa and Sanjay Joshi proposed using a 3D printer with a movable build plate or extrusion arm to turn objects in 3D space as they’re printed, thereby making every surface “flat” as its being extruded.